The discription of the four nozzles fuel station filling equipment

1. 1 MPD Dispenser with 2 product, 4 nozzle.

2. Pumping unit for discharge the oil from truck to Tank.

3. 1 Canopy available with Solar panel.

Solar power 4 nozzles fuel dispenser directly converts sunlight into electric energy by using photoelectric effect, and the power generation process does not produce any pollution, which is attracting the attention of more and more countries. The photovoltaic power generation system is mainly composed of photovoltaic cell modules, controllers and inverters. Inverter machine is to convert the DC energy generated by the power generation system into AC energy. Besides, our company also sell mini portable fuel dispenser, it is easy to carry.There are several types of nozzles, Model available for 1 nozzle, 2 nozzle, 4 nozzle, 6 nozzle, 8 nozzle.So we can provide single nozzle fuel dispenser double nozzle fuel dispenser, and so on.

Welcome to your consultation.

Technical Parameter

| Accuracy |

±0.30%

|

|

Repeating Accuracy

|

≤0.10%

|

|

Flow Range

|

(5~55) L/min

|

|

Maximum Head

|

5m

|

|

Inlet Vacuum

|

≥54kPa

|

|

Outlet Vacuum

|

≤0.3MPa

|

|

Work Pressure

|

<300kPa

|

|

Noise

|

≤70dB(A class)

|

|

Unit Price Range

|

0~9999, 0~999999 (Changeable)

|

|

Single Range

|

1~9999.99,1~999999.99 (Changeable)

|

|

Accumulative Range

|

0~9999999999.99

|

|

Input Hose Diameter

|

38mm

|

|

Oil Hose Diameter

|

19mm

|

|

Explosin-Proof Motor Power

|

750W(or 1000W)

|

|

Ambient Temperature

|

-35℃~+55℃

|

|

Humidity

|

≤95%

|

|

Atmospheric Pressure

|

86kPa~106kPa

|

|

Power(optional)

|

AC110V±20%, AC220V±20% , AC380V±20% (50Hz)

|

| Hose |

3m(low hang), 4.5m(high hang) |

| Nozzle |

Auto Shut-off Nozzle |

| Suction distance |

6m(Vertical), 50m(horizontal) |

| Accessories |

Motor, Pump, Flow Meter, Controller, Nozzle |

| LCD Display |

664, 885, Digital, Mechanical Analog |

| POS/Protocol |

Tatsuno, Gaskit, Ifsf, Pts, Itl, PT etc. |

| Controller |

Electric,Meachanical |

| Transport Package |

Carton, Wood Case |

| Medium |

Petrol, Gasoline, Kerosene, Diesel, Adblue |

| Flow Meter |

Bennett, Tokheim, Tatsuno, Gilbarco, Wayne, Tokico |

| Nozzle |

Opw, Zva, Tatsuno, Husky, Healy, Automatic |

| Certificate |

OIML, CE, Atex, Sira, Coc, Soncap, Saso, Nrcs, CMC |

| Hose Pcs |

1,2,4,6,8 |

1.Electronic calibration

2.Voice and printer (According to your reqirement)

3.Fueling times limit function

4.Function of locking pump

5.Stop fueling by integer sale

6.Can set the decimal point for the display, so can be used in many country with different currency rate

7.Leaves the communication ports, so it can communicate with the gas station management system

8.Can communicate with the IC card reader

Product Display

We can do OEM & ODM for fuel dispenser, logo on the light or package both is available.And our company was certified ISO9001, ISO14001, ISO10012, OHSAS18001, UL, ATEX, etc.Please write down all your questions. And click send, we will reply you by mail in 24 hours.

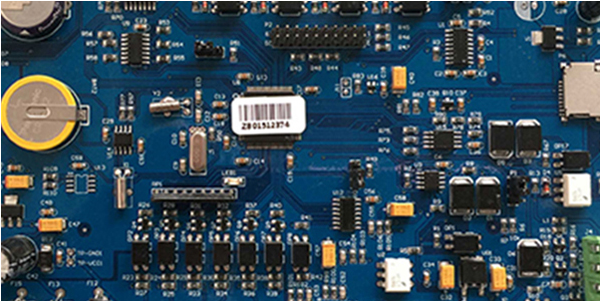

Main Parts

Equipped with high-performance 32-bit scalable arm motherboard.

Mainboard multilayer circuit design,

A variety of anti-interference measures are adopted to fully meet the environmental requirements of electrostatic impact, electromagnetic interference, sudden voltage drop, surge impact and so on.

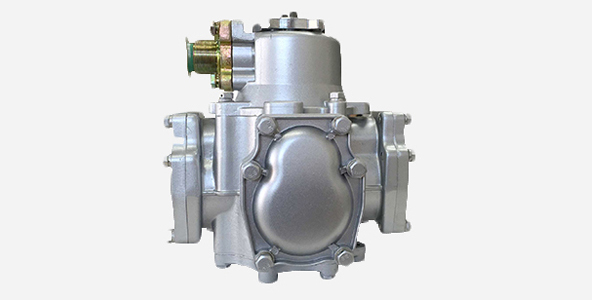

The high-precision soft piston flow measurement converter (meter) adopts aluminum alloy high-pressure die-casting, with small volume and light weight.

The key parts are made of special stainless steel and engineering plastics, with corrosion resistance, wear resistance and excellent dynamic sealing performance.

The transmission shaft is driven by a push-pull structure composed of piston rod and crankshaft, without intermission, impact and abnormal noise.

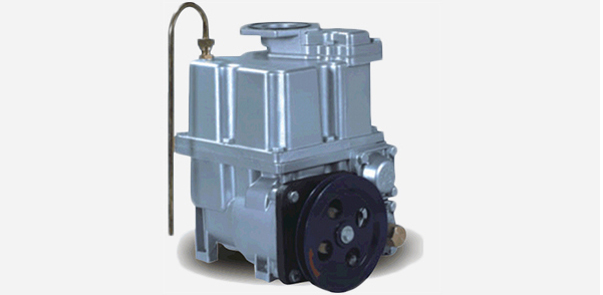

The Pump(Optional)

The combined pump is made of aluminum alloy high-pressure die-casting, with light weight.

The internal blade compensation technology is adopted, and the combined pump operates stably with low noise.

The gear pump is made of higher quality aluminum alloy composite material by die casting, so that leakage rarely occurs.

Centrifugal oil-liquid separation is adopted inside, which has strong oil-gas separation ability. Especially in hot weather environment, the oil absorption performance is very excellent, which is suitable for various complex environments.

The submersible pump fundamentally eliminates the phenomenon of air resistance, and completely solves the problems that the self-priming pump cannot solve under the conditions of high temperature, high lift and long distance, such as less oil output (gas-liquid two-phase), environmental pollution, and even no oil.